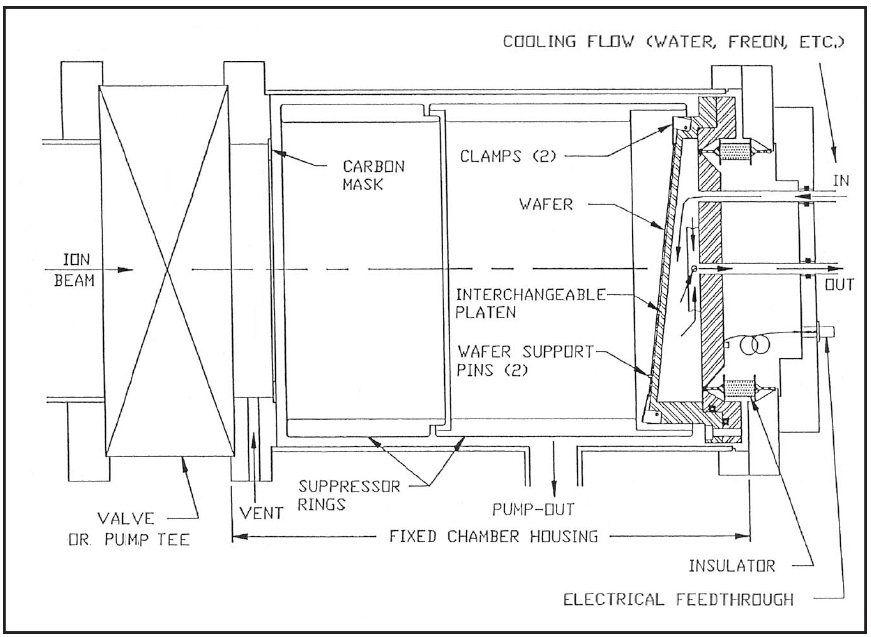

The implant endstation is a manual single wafer handler. The chamber is designed to ensure accurate dose monitoring with uniform deposition.

The wafer is attached to a platen, which can be electrically heated from 0°C to 500°C with a 7° tilt from the beam axis. The platen is mounted on a flange for access. Beam current is measured on the platen to determine dose using a dose integrator. The chamber supports 6″ (15 cm) wafers. Custom chambers for larger wafers may be available.

Immediately in front of the wafer are two suppression rings of opposite polarity. These rings are designed to suppress ions and electrons coming from the wafer in order to maintain an accurate dose reading. There is a carbon mask holder immediately in front of the suppression rings. The beam overscan is incident on the carbon mask.

The fixed chamber housing contains a roughout port, as well as a vent inlet located near the beam entrance. A pneumatic gate valve is positioned on the chamber entrance, prior to which is a turbo-molecular pump station to pump the beamline and endstation.

A high temperature implant endstation is also available, which can be electrically heated to 550° C

Please contact NEC for further information